|

HOTFIL hot filament electrodes

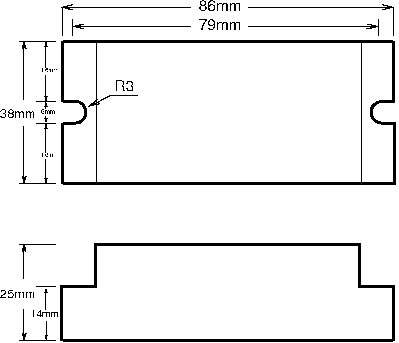

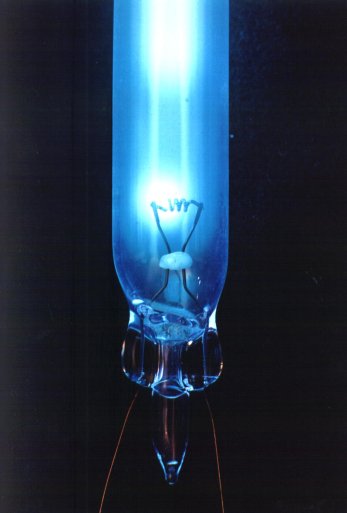

A product of German precision manufacture. Fits almost every application with operating currents from 50 to 700mA. Types A and B preferrably for use with the HOTFIL "mini EPS" Electronic Power Supply. Type C for operating with standard 58 W-ballasts*). Tubes with HOTFIL electrodes can be processed... ...without vacuum oven, on Neon pumping systems ...with a vacuum oven like normal fluorescent For all tubes with blue discharge (mercury vapor, no Neon). Tubes can also be operated in high voltage series circuits without preheat! Operation of HOTFIL-electrodes on socalled T5-"Multiwatt" electronic ballasts of third party manufacturers (automatic wattage detection) is not yet recommended. |

|